Internal Floating Roof Installation Procedure

Refiners derived significant advantage through the floating roofs which are used to store very large volumes from super tanker shipments and meet the escalating demand for hydrocarbons in industry.

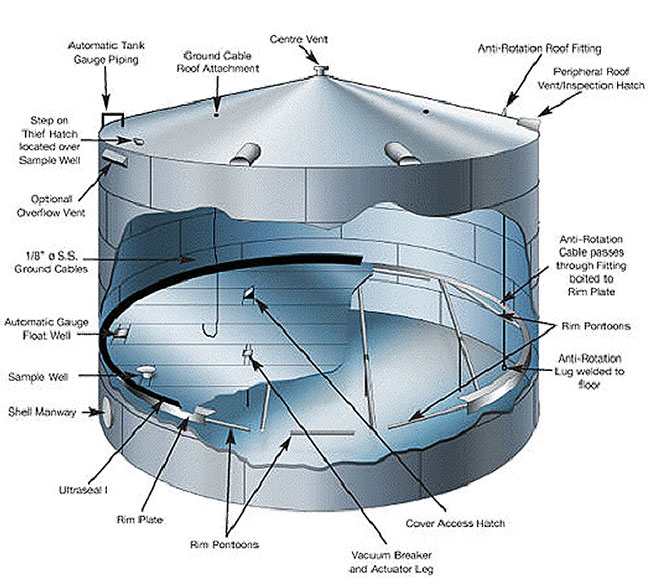

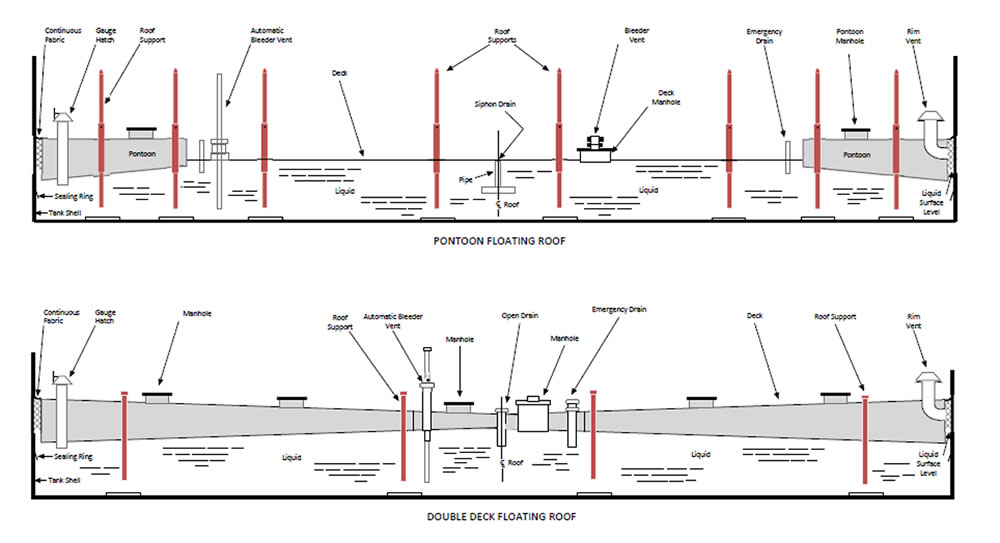

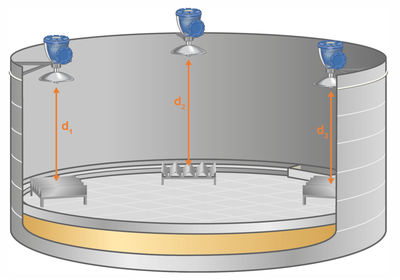

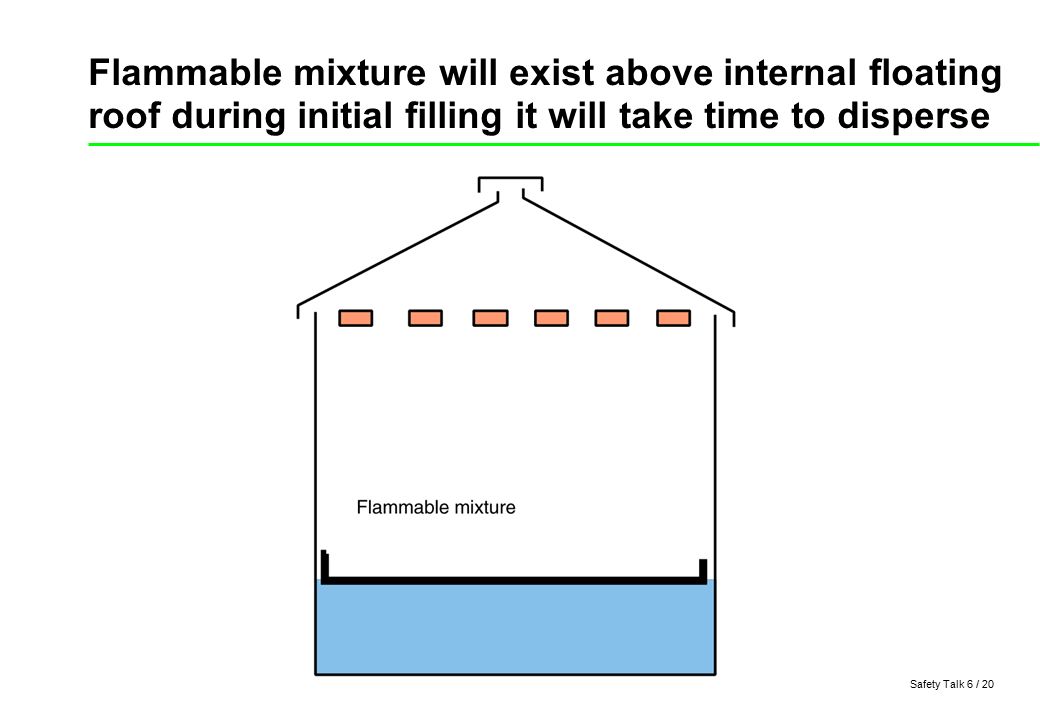

Internal floating roof installation procedure. One of the biggest tank that built in the project is product methanol tank with type dome roof with internal floating roof shell size 63 metres inside diameter and 18 metres height dome roof radius is 50 4 metres and internal floating roof diameter is 62 6 metres. Storagetech storage tank internal floating roofs storagetech has been proudly innovating designing manufactiring and installing external and internal pon. Floating roof tank can be divided into two types internal floating roof and external floating roof. Floating roof tank has built in buoyancy that allows the roof to float on top of the content in open or closed top tank.

33m ø x 14 6m ht. Truss supported fixed cone roof storage tank for aviation jet fuel 1 no. Floating roof tank is which the roof floats directly on top of the. Over the past 60 plus years thousands of tanks with fixed roofs with internal covers and floating roofs have been used to store crude oil and middle distillates.

An internal floating roof tank is a floating roof tank fixed an extra fixed roof on the floating roof to prevent floating roof from wind and rain and guarantee the quality of the stored oil. These tanks and structures include process vessels stacks ducting penstocks digester roofs and internal floating roofs. Floating roof tank etc. External floating roof and internal floating roof.

Because the flexible floating roof deck can float up and down to close to the liquid level gas space above the liquid level can be greatly reduced thereby greatly reducing the evaporation loss of the stored oil. 4 nos 17mtrs ø x 11 6mtrs. Longitudinal forces acting on thin cylinder under internal pressure 47 figure 2 2. 1 no 7mtrs.

There is limited procedure and rules in designing the floating roof which result lots of floating roof failure and caused injuries and fatalities accident. Tank construction was done from september 2008 to october 2009. Floating roof is the core component of floating roof storage tank which is divided into two types.