Internal Floating Roof Tank Level Measurement

Roof mounted installation with guided wave radar an alternative solution is to use up to six guided wave radar level transmitters directly on the floating roof with rigid probes penetrating through the roof and into the liquid below.

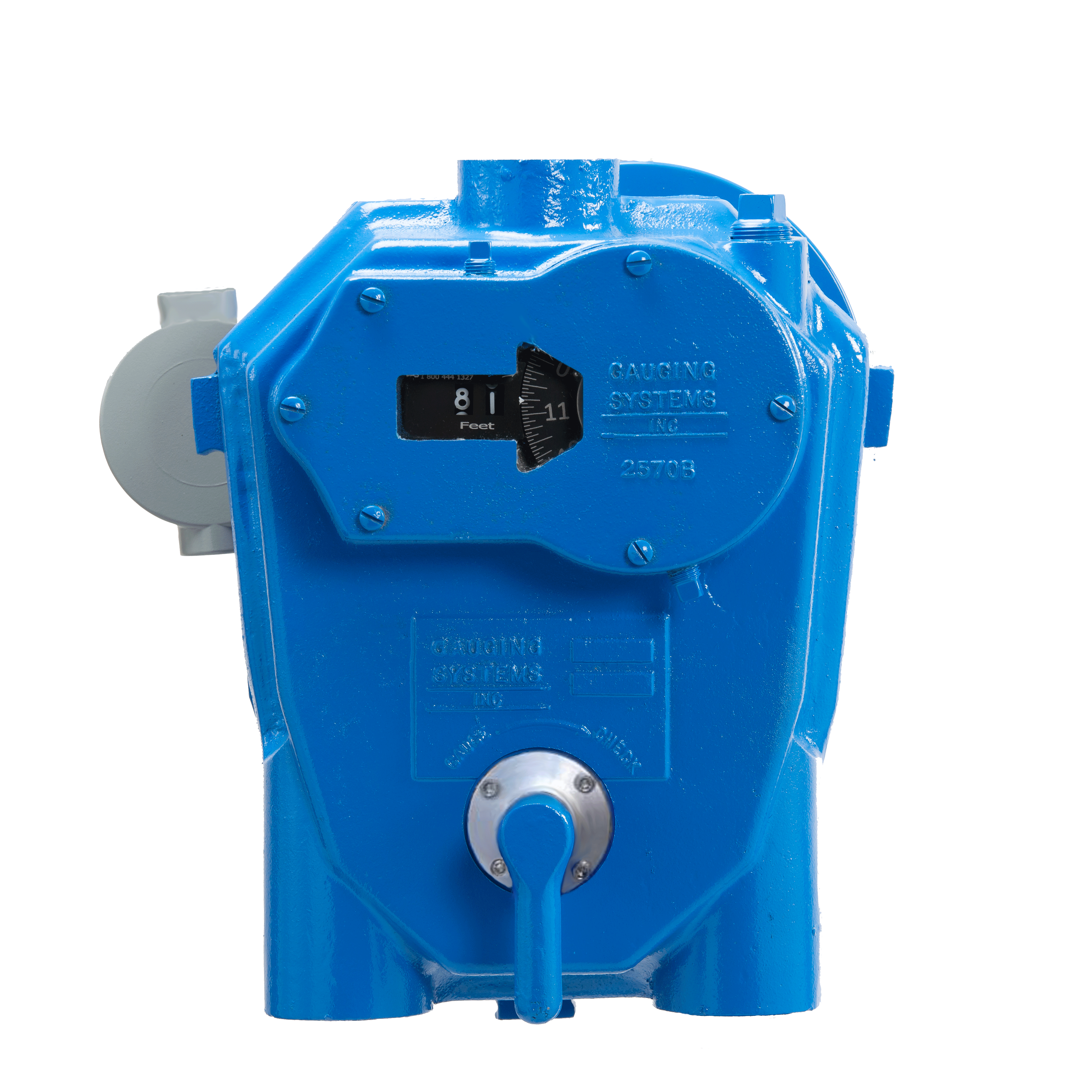

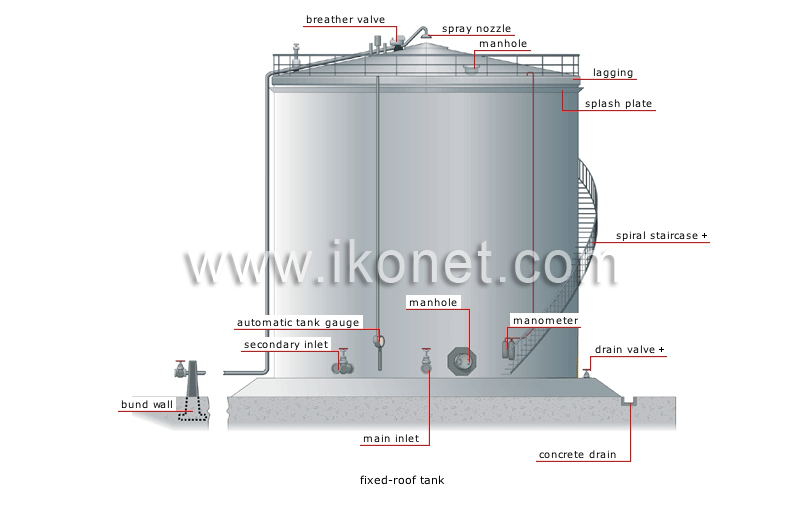

Internal floating roof tank level measurement. These level instruments can also be used as part of an overfill prevention system. This new technology from emerson enables automatic monitoring of roof position with radar devices mounted on the tank. Internal floating roof tank parameter as follows. Floating roof tanks are broadly divided into internal ifr and external efr floating roof tanks.

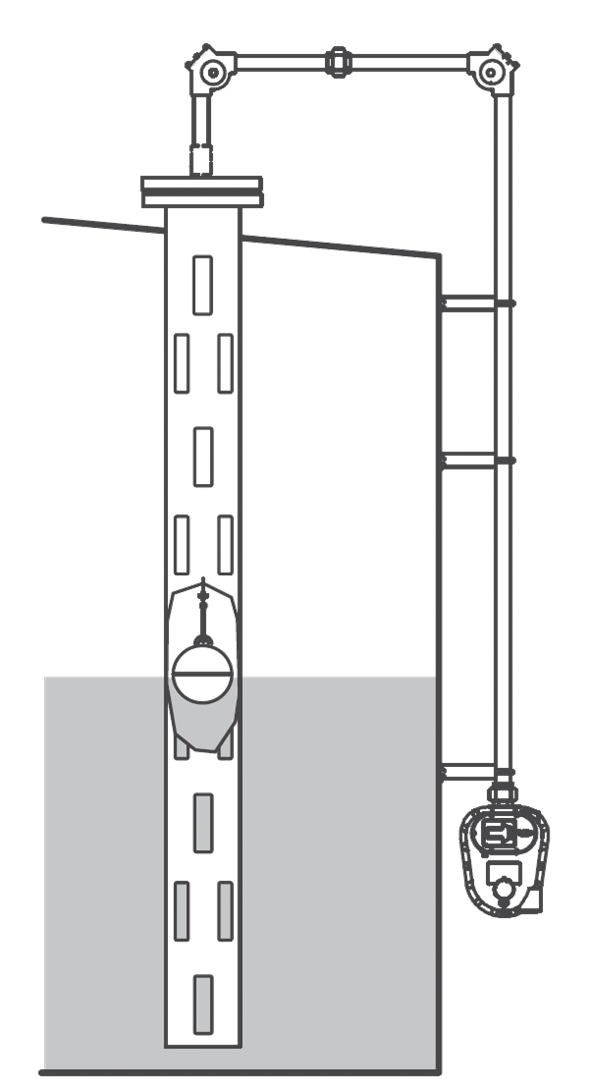

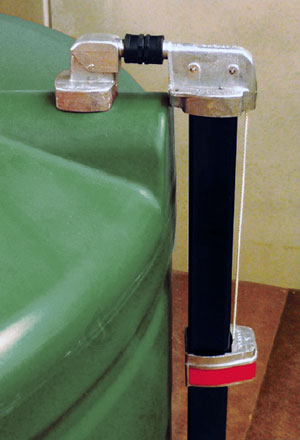

These tanks are nothing more than cone roof tanks with a floating roof inside the tank which travels up and down along with the liquid level. The second approach is to install three or more wireless guided wave radar measurement instruments in which the probes penetrate through the roof down into the tank to measure the airspace above the liquid. We will now contact some vendors to make sure the solution. Internal floating roof tanks level switch installation.

As the manufacturing and the installation of the internal floating roof is fairly quick it does not cause the tank to stay out of usage for a long time. Various oil products including naphtha gasoline diesel kerosene crude oil fuel oil heavy oil benzene xylene methanol ethanol etc. With the availability of guided wave radar devices with iec 62591 wireless communications instrumentation wiring at the tank is not required. Ifr tanks are used for liquids with low flashpoints e g.

Adding the tank level measurement as a reference means that roof buoyancy can also be monitored. Spacing 3 or more non contacting radar measurement instruments around the tank provides a measurement from the top of the tank shell down to the floating roof level inside the tank. Storage tank internal floating roof designed and manufactured in order to be to pass from 20 and 24 inches manholes and assembled in the tank. A sinking or tilting roof can result in mechanical damage and lead to vapor release product contamination and fire hazard.

Having the level measured at 3 spots provides a comparison on how the roof is floating and helps spot tilt conditions.