Kennedy Metal Seated Gate Valve

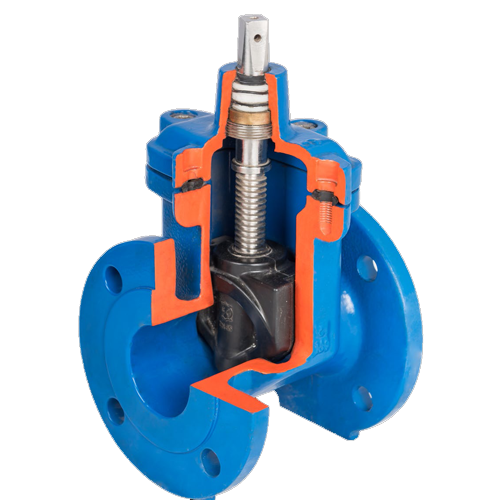

The body features a full free open passageway equal to the nominal line size to minimize pumping losses.

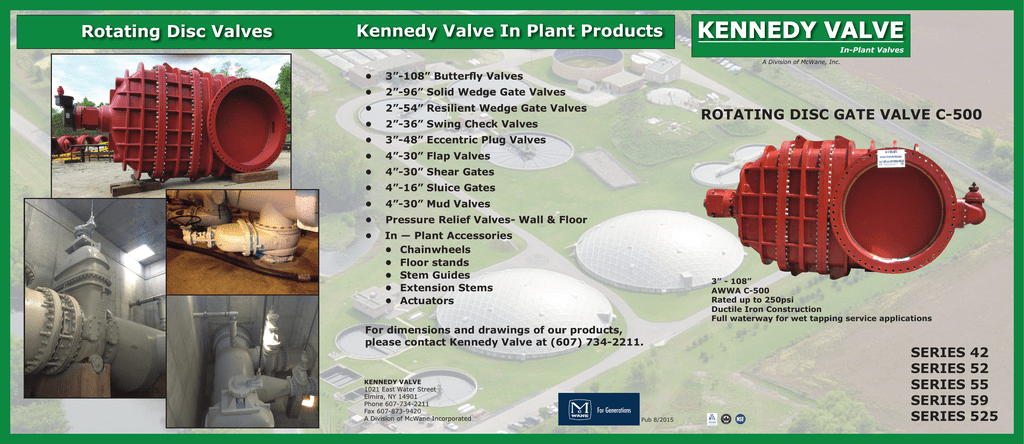

Kennedy metal seated gate valve. Gate valves the clow resilient wedge valve with its unique features and benefits was the first to be manufactured with both awwa and ul fm approval for all water system requirements. Ks rw gate valve c515 14 54 in america today systems are increasing their demand for larger sized water lines. Gate valves kennedy valve awwa c500 metal seated gate valves meet or exceed the requirements of awwa standard c500 size range water working pressure psi seat test pressure psi hydrostatic shell test pressure psi awwa 3 108 250 water works 250 500 contact kennedy valve for sizes larger than 48. Standard for resilient seated gate valves for water supply service.

Submittal sheet c515 30 54 geared. This kennedy valve general maintenance guide is intended to cover awwa c509 c515 ul 262 and fm 1120 1130 valves. The vsi waterworks gvii is based off the tried and true metal seated wedge gate valve design which is available in sizes of 2 to 72. Kennedy valve does not recommend.

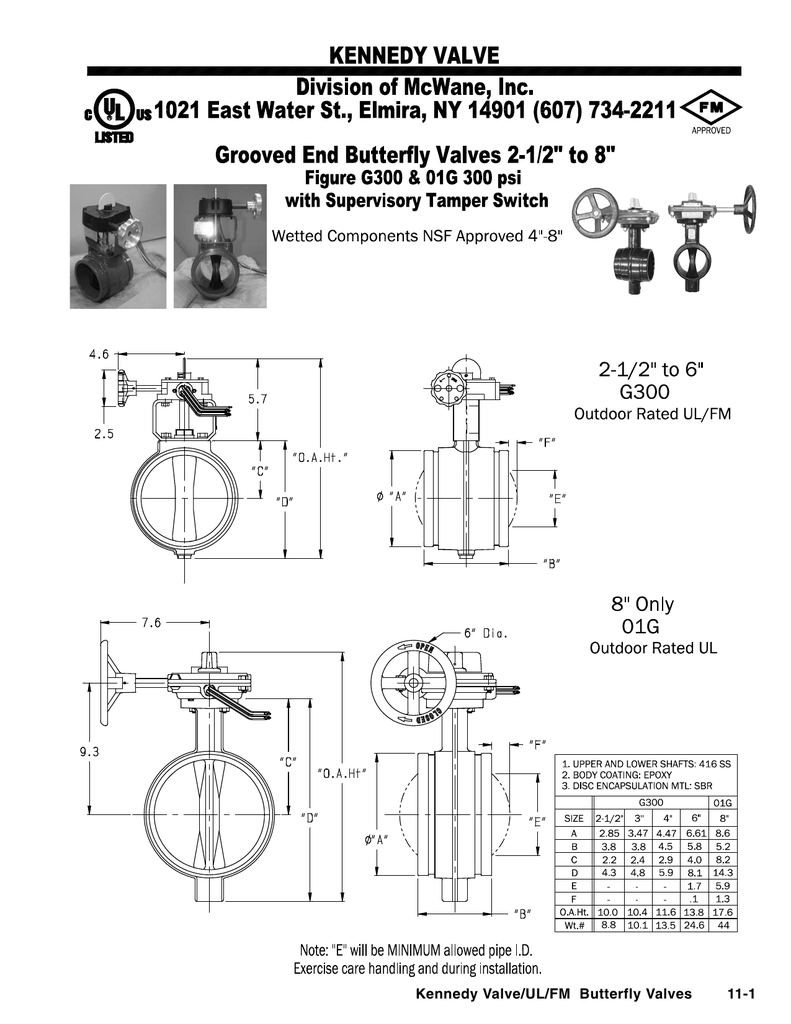

Herewith sand and pebbles are embedded in the bore. The simple two moving component construction practically eliminates. In the 135 plus years since its founding kennedy valve has expanded to be a full line waterworks valve and hydrant manufacturer supplying resilient seated gate valves fire hydrants check valves butterfly valves indicator posts grooved butterfly valves and an assortment of related products and appurtenances. Submittal sheet c515 14 24 geared.

These valves meet all requirements of awwa c500 latest revision and applicable ansi astm and other industry standards. Before the resilient seated gate valve was introduced to the market gate valves with a metal seated wedge were widely used. 3 54 valves are rated at 250 psi and hydrostatically tested to 500 psi ductile iron construction. The conical wedge design and angular sealing devices of a metal seated wedge require a depression in the valve bottom to ensure a tight closure.

The gate features two independent seating surfaces and is fully bi directional. With these growing demands kennedy valve company has made the commitment to meet and surpass previous large resilient seated gate valve requirements. Standard for metal seated gate valves for water supply service. Products meet and exceed the.

In 1890 the operation was moved to coxsackie and then in 1907 kennedy valve moved to elmira n y where it remains a cornerstone of the community. Standard for protective interior coatings for valves and hydrants. Kennedy valve began operations in 1877 in lower manhattan n y. Clow valve was the first to introduce and still leads in the design and technical development of the bubble tight resilient seating valve.